Integrated Assessment of Palm Oil Mill Residues

- Usage:Palm oil, Cooking oil or High grade oil

- Type:Cold & Hot Pressing Machine

- Automatic Grade:Automatic

- Production Capacity:30TPD Vegetable oill Production Machine

- Voltage:380V,220V

- Power(W):Based On Vegetable oill Production Machine Capacity

- Dimension(L*W*H):Based On Vegetable oill Production Machine Capacity

- Weight:Based On Vegetable oill Production Machine Capacity

- Certification:CE,BV

- After-sales Service Provided:Engineers available to service machinery overseas

- Oil standard:Equals to EU,American grade

- Phosphoric acid:2~3kg/T oil

- Working mode:Continuous or Semi-continuous

- Steam consumption:450kg/T oil

- Waste bleaching earth oil content:<35%

- Deodorization loss consumption:<0.5%

- Bleaching earth consumption:5~50Kg/Toil

- Packaging:Glass Bottle, Bulk, Can (Tinned), Plastic Bottle

- Refined Type:Vegetable oill Production Machine

Integrated Assessment of Palm Oil Mill Residues to Sustainable Electricity System (POMR-SES): A Case Study from Peninsular Malaysia Tools RDF+XML BibTeX RDF+N-Triples JSON RefWorks Dublin Core Simple Metadata Refer METS HTML Citation ASCII Citation OpenURL ContextObject EndNote OpenURL ContextObject in Span MODS MPEG-21 DIDL EP3 XML Data Cite XML Reference Manager RDF+N3 Multiline CSV

Critical Parameters in The Life Cycle Inventory of Palm

- Usage:palm oill Production

- Type:palm oill Production

- Automatic Grade:Automatic

- Production Capacity:5-50TPD

- Voltage:380V/3 phase

- Power(W):palm oill Production

- Dimension(L*W*H):palm oill Production

- Weight:palm oill Production

- Certification:CE

- After-sales Service Provided:Engineers available to service machinery overseas

- Item:palm oill Production

- Supplier type:Manufacturer

- Function:Refining

- Texture:Mild steel and SS

- Raw material:Crude palm oil

- Final product:Refined cooking oil

- Model type:Continuous

- Handling capacity:5-50 tpd

- Main market:Africa and Malaysia

- Service scope:Installation, training, etc.

The environmental impact of palm oil production is a global concern that has been scrutinized by the scientific community. Co-composting palm oil mill by-products (empty fruit bunch – EFB and palm oil mill effluent – POME) has been promoted as an efficient way to reduce environmental footprint.

Environmental load assessment for an integrated design

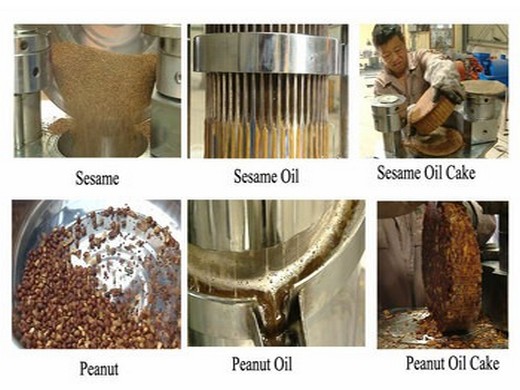

- Usage:groundnut oil expeller machine

- Type:Cold & Hot Pressing Machine

- Automatic Grade:Automatic

- Production Capacity:100%

- Voltage:380/220V

- Power(W):according to actual process capacity

- Dimension(L*W*H):according to actual process capacity

- Weight:according to actual process capacity

- Certification:CE

- After-sales Service Provided:Engineers available to service machinery overseas

- Bank credit rating:AAA

- certificate:ISO9001&CE

- Capacity:5t-3000t

- Function:press various kinds of oil seeds

- Raw material:oil seeds,Palms

- Warranty:1 year

- Service life:20 years

- After sale service:design the workshop/ installation/ training workers

The comprehensive life cycle assessment for integrated palm oil and microalgae production system are presented in Table 3, Table 4. Table 3 summarized the material and energy balances for the palm oil-based biodiesel production cycle. In the nursery phase, material inputs for palm oil production include fertilizers, plant protection chemicals and water.

WT24 A survey on the usage of biomass wastes from palm oil

- Usage:crude palm kernel oill Mill

- Type:crude palm kernel oill Mill

- Automatic Grade:Automatic

- Production Capacity:99%

- Voltage:200v/380V/400V

- Power(W):10-80KW

- Dimension(L*W*H):crude palm kernel oill Mill

- Weight:crude palm kernel oill Mill

- Certification:ISO&CE&BV

- After-sales Service Provided:Engineers available to service machinery overseas

- specifications:crude palm kernel oill Mill

- certification:CE ISO

- Raw material:crude palm kernel oil

- final product:refined palm kernel oil

- capacity:1-3000TPD crude palm kernel oill Mill

- function:crude palm kernel oill Mill

- color:according to customer

- service life:90 years

- service after sale:workshop design/installation/training

- warranty:1 year

biomass wastes from palm oil mills and its impact on sustainable development of oil palm plantations in Sarawak. 253 planters across Sarawak were approached for their opinions about the usage of empty fruit bunch (EFB), palm oil mill effluent (POME), mesocarp fibre (MF), and palm kernel shell (PKS).

Life cycle assessment of composting of palm oil residues

- Usage:Palm

- Type:Cold & Hot Pressing Machine, Screw oil press machine

- Automatic Grade:Automatic

- Production Capacity:150~250kg/h

- Voltage:380V

- Power(W):7.5KW

- Dimension(L*W*H):1.95x1.3x1.9m

- Weight:950kg

- Certification:ISO9001

- After-sales Service Provided:Engineers available to service machinery overseas

- Staff:1-2 people

- Pressure adjustment mode:Worm adjustment

- Material:Stainless steel and Carbon steel

- Plant size:30-50 square meter

Palm Oil Mill Effluent (POME) Empty Fruit Bunches (EFB) Fig 1: Water pollution due to EFB and POME More than 40 million tonnes of palm oil has been produced last year. For producing I t crude palm oil (CPO) 5 t fresh fruit brunches (FFB) are required while 1.15 t empty fruit bunches (EFB) and 3.75 t palm oil mill effluent (POME) are generated.

Land application of biomass residue generated from palm

Compared to conventional palm oil mills the total amount of palm oil mill effluent (POME) can he reduced from 0.65 m3 t FFB to 0.45 rn3 t (conventional sterilization and zero dilution water) and 0

GET PRICE

Critical Parameters in The Life Cycle Inventory of Palm

Baron et al. / IJoLCAS 3, 1(2024) 25 Critical Parameters in The Life Cycle Inventory of Palm Oil Mill Residues Composting Victor Baron a, Mohamed Saoud , Joni Jupestab, Ikhsan Rezky Praptantyob, Hartono Tirto Admojob, Cécile Bessoua, Jean Pierre Caliman a CIRAD, Systèmes de pérennes, Avenue Agropolis, 34398 Montpellier Cedex 5, France b SMART Research Institute, Jl. Teuku Umar No. 19, Pekan

GET PRICE

Chapter 13 Utilization of oil palm co-products as feeds

owner of oil palm land. As of 2009, there were 252 oil palm mills and 36 refineries in Peninsular Malaysia, 117 oil palm mills and 11 refineries in Sabah, and 41 oil palm mills and 5 refineries in Sarawak. Over the period 1990–2005, the land area under oil palm increased by 6.6˛percent per Chapter 13 Utilization of oil palm co-products as feeds

GET PRICE

Production Cost Assessment of Palm Empty Fruit Bunch

Abstract Production cost assessment was based on palm oil mill of 30 metrics tons FFB/h capacity that produced EFB residue at — app. 20 % wt of the initial FFB fed to the plant. The bio-oil plant will be located in the palm oil mill complex to eliminate the transportation cost of the EFB feedstock.

GET PRICE

Palm oil mill effluent | Feedipedia

Palm oil mill effluent is a highly polluting material, due to its high biological oxygen demand (BOD), low pH and colloidal nature. It was estimated that a processing plant with a capacity of 10 tons fresh fruit per hour would need a water treatment plant comparable to that required by a population of half a million inhabitants (Brezing, 1986).

GET PRICE

3. PALM OIL PROCESSING - | Food and Agriculture

3. PALM OIL PROCESSING 3. 1 General processing description. Research and development work in many disciplines - biochemistry, chemical and mechanical engineering - and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a

GET PRICE

Production Cost Assessment of Palm Empty - Engineering

Production cost assessment was based on palm oil mill of 30 metrics tons FFB/h capacity that produced EFB residue at app. 20 % wt of the initial FFB fed to the plant. The bio-oil plant will be located in the palm oil mill complex to eliminate the transportation cost of the EFB feedstock. The process included in this calculation is chopping, drying, grinding, pyrolysis, solid removal, bio oil

GET PRICE

Flow chart of the production chain of palm oil and palm

Transport to the oil mill Palm fruits (2) Production of crude oil Risk assessment of the chain of palm and palm kernel oil products 1. Cultivation of palm fruits* , INDUSTRY STANDARDS AND/OR CONTRACT TERMS CONTROL MEASURE REMARKS Pesticide residues above the EU MRL, i.e. residues of herbicides, insecticides, fungicides or rodenticides

GET PRICE

Energetic Use of Palm Oil Residues in Indonesia and Thailand

Energetic Use of Palm Oil Residues in Indonesia and Thailand One of the key measures for climate change mitigation is the energetic use of biomass. According to the Inter-national Energy Agency (IEA) the share of bioenergy in global primary energy supply could sustainably increase from currently 10% to 33% in 2050. Vast resources in

GET PRICE

Greenhouse gas reductions through enhanced use of residues

1 Greenhouse Gas Reductions through Enhanced Use of Residues in the Life Cycle of Malaysian Palm Oil derived Biodiesel . Sune Balle Hansena,b, Stig Irving Olsena, Zaini Ujangc a DTU Management Engineering, Technical University of Denmark, Produktionstorvet building 424, 2800 Kgs.

GET PRICE

Oil palm fronds and oil palm crop residues | Feedipedia

Oil palm fronds can support an efficient rumen function in terms of NH 3-N concentration when 50% or more is used in the diet, but the latter requires additional fermentable N (Islam et al., 2000a). Dairy cattle. Cows fed 30% oil palm fronds silage and 70% palm kernel-based concentrate produced more milk than those fed 50% oil fronds or 50% grass.

GET PRICE

REVIEW ON DENSIFICATION OF PALM RESIDUES AS A TECHNIQUE

Due to the tremendous amount of palm biomass residues produced during the palm oil extraction from fresh fruit bunch (FFB), it is inevitable to harness these biomass energy sources to cope with the depletion of fossil fuels and increase in global energy demand scenarios.

GET PRICE

A meta‐analytic review of life cycle assessment and flow

The palm oil biodiesel production system assessed by the reviewed studies can be divided in 5 major steps (Figure 1): A) land preparation, B) oil palm plantation, C) palm oil mill, E) conversion to biodiesel fuel, and E) use of biodiesel fuel (BDF). Depending on which unit processes are considered in the assessment, studies are classified into

GET PRICE

Energetic Use of Palm Oil Residues in Indonesia and Thailand

Energetic Use of Palm Oil Residues in Indonesia and Thailand One of the key measures for climate change mitigation is the energetic use of biomass. According to the Inter-national Energy Agency (IEA) the share of bioenergy in global primary energy supply could sustainably increase from currently 10% to 33% in 2050. Vast resources in

GET PRICE

LABOUR RIGHTS ASSESSMENT: NESTLÉ’S PALM OIL SUPPLY CHAIN

Palm oil accounts for 35 percent of the world’s vegetable oil consumption and is used in almost 50 percent of supermarket products. Indonesia is the largest producer of palm oil in the world, and an estimated 3.7 million people are engaged in the palm oil industry and downstream industries, according to a 2011 Roundtable

GET PRICE

Technical polygeneration potential in palm oil mills

Technical polygeneration potential in palm oil mills in Colombia: A case study. Salomon Popa, Marianne The assessment of the palm oil residues consisted on a technical analysis of the possible alternatives for electricity, heat, and biofuels production. The assessment of biomass power plant integrated with the Swedish industry

GET PRICE

3. PALM OIL PROCESSING - | Food and Agriculture

3. PALM OIL PROCESSING 3. 1 General processing description. Research and development work in many disciplines - biochemistry, chemical and mechanical engineering - and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a

GET PRICE

1. INTRODUCTION

Modern processing of oil palm fruit bunches into edible oil is practiced using various methods, which may be grouped into four categories according to their throughput and degree of complexity. These are the traditional methods, small-scale mechanical units, medium-scale mills and large industrial mills.

GET PRICE

3. PALM OIL PROCESSING - | Food and Agriculture

3. PALM OIL PROCESSING 3. 1 General processing description. Research and development work in many disciplines - biochemistry, chemical and mechanical engineering - and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a

GET PRICE

Techno-economic Assessment of an Integrated Algae-based

The utilisation of algae for POME treatment coupled with biogas facilities in the palm oil mill can simultaneously remediate the wastewater and reduce the cost for nutrient and freshwater supplies required for algae growth. This paper investigates the techno-economic potentials of an integrated algae-based bio- refinery with palm oil mill.

GET PRICE

TASK 4 Integrated Assessment Final

Figure 36: Palm oil planting and a palm oil plantation in Indonesia. 137 Figure 37: Ethanol exports and imports for US. The US exports more ethanol to Brazil than it imports, except for California, which uses 30% or more of all Brazilian sugarcane ethanol imports. (USDA‐ERS) 138

GET PRICE

LABOUR RIGHTS ASSESSMENT: NESTLÉ’S PALM OIL SUPPLY CHAIN

Palm oil accounts for 35 percent of the world’s vegetable oil consumption and is used in almost 50 percent of supermarket products. Indonesia is the largest producer of palm oil in the world, and an estimated 3.7 million people are engaged in the palm oil industry and downstream industries, according to a 2011 Roundtable

GET PRICE

Compilation of Best Management Practices to Reduce Total

construction. Terusan Palm Oil Mill developed its methane capture facility, a Covered In-Ground Anaerobic Reactor (CIGAR), in 2015, and it became operational in 2024. Case study 4: Filter belt-press (KLK Berhad) A major issue that all palm oil mills are faced with is how to manage their palm oil mill effluent (POME), the liquid

GET PRICE

Palm Oil - the sustainable 21st century oil

Palm Oil - the sustainable 21st century oil. Palm oil (PO) is the world’s most widely produced and traded vegetable oil. It is predominantly used for food, but increasingly also for personal care products and more recently as a feedstock for biodiesel.

GET PRICE

Energy Potential of Coconut and Palm Oil Residues

Biodiesel is produced by transesterification of palm oil/coconut oil. The required process heat for palm oil or coconut oil processing as well as the steam required for biodiesel production is supplied by the combustion of the residues. The results show that palm oil mills/coconut processing industries can be independent of fossil fuels.

GET PRICE