BEST Oil Manufacturing Plant, Palm Oil Making Machines

- Usage:Palm Oil, Cooking oil or High grade oil

- Type:Cold & Hot Pressing Machine

- Automatic Grade:Automatic

- Production Capacity:5-500TPD Palm oill Plant

- Certification:CE,BV

- After-sales Service Provided:Engineers available to service machinery overseas

- Oil standard:Equals to EU,American grade

- Working mode:Continuous or Semi-continuous

- Phosphoric acid:2~3kg/T oil

- Steam consumption:450kg/T oil

- Waste bleaching earth oil content:<35%

- Bleaching earth consumption:5~50Kg/Toil

- Deodorization loss consumption:<0.5%

- Packaging:Glass Bottle, Bulk, Can (Tinned), Plastic Bottle

- Refined Type:Palm Oil Refined

The screw press is the most commonly used palm oil making machine in both small and large scale palm oil manufacturing plant due to its high oil extraction rate. Palm Oil Clarification Station: The purpose of clarification in palm oil manufacturing process is to remove impurities. The final crude palm oil will be storage in bulk in a tank.

Advanced Palm Oil Manufacturing Process and Machine

- Usage:Palm Oil

- Type:Cold & Hot Pressing Machine, Refined Palm Oil Equipment

- Automatic Grade:Automatic

- Production Capacity:30-500TPD Refined Palm Oil Equipment

- Voltage:380V

- Power(W):Based on Refined Palm Oil Equipment capacity

- Dimension(L*W*H):Based on Refined Palm Oil Equipment capacity

- Weight:Based on Refined Palm Oil Equipment capacity

- Certification:ISO9001

- After-sales Service Provided:Engineers available to service machinery overseas

- Material:Stainless and Carbonless Steel

- Pretreatment Process:Cleaning,Hulling,Breaking,Soften,Flaking,Puffing,Toasting

- Raw Material:Vegetable Oil Suitable for Palm Kernel,Palm

- Cooking Oil Machinery Process:Pre-treatment,Solvent Extraction,Refining

- Solvent Extraction Process:DTDC,Miscella Toasting and Stripping,Solvent Collecting,etc

- Refining Process:Degumming,Deacidification,Deordorization,Decoloration,etc

- Process Capacity:30-500TPD

- Service:Engineer Abroad Erection

- Packing:Frame and Container

Palm Oil Manufacturing Process. The palm oil manufacturing process is briefly described below. ABC Machinery can provide all the equipment for palm oil production. (You may also like: Cost of Setting up a Palm Oil Mill in Nigeria >>) Mini Palm Oil Mill Manufacturing Process and Equipment. Palm Fruit Receiving and Storage

Palm Oil Mill Processing Machines - Palm Oil Mill Machine

- Usage:Palm Oil

- Type:Cold & Hot Pressing Machine, Red Palm Oil Refining Machine

- Automatic Grade:Automatic

- Production Capacity:300TPD Red Palm Oil Refining Machine

- Voltage:380V

- Power(W):Based on Red Palm Oil Refining Machine capacity

- Dimension(L*W*H):Based on Red Palm Oil Refining Machine capacity

- Weight:Based on Red Palm Oil Refining Machine capacity

- Certification:CE,BV,ISO9001

- After-sales Service Provided:Engineers available to service machinery overseas

- Raw Material:Palm Fruit,Palm Kernel

- Material:Stainless,Carbonless Steel

- Process:Prepress,Extraction,Refinery

- Process Capacity:300TPD Red Palm Oil Refining Machine

- Oil Quality:Equals to EU Standard

Palm Oil Mill Plant Flow Chart Introduction: 1.Palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge. 2.Palm oil mil process of sterilization: the use of high temperature to cook soft fruit bunches and sterilization, easy to separate fruit bunches, soft fruit, increasing the humidity of

palm oil manufacturing process - Oil Mill Plant

- Usage:Palm oil

- Type:Palm oil refinery

- Automatic Grade:Automatic

- Production Capacity:10T-3000T/D

- Voltage:220V/380V

- Power(W):Palm oil machine accoding to your capacity

- Dimension(L*W*H):Palm oil machine accoding to your capacity

- Weight:Palm oil machine accoding to your capacity

- Certification:ISO9001

- After-sales Service Provided:Engineers available to service machinery overseas

- Iterm:Oil machine press palm

- Electric consumption:28Kwh/T oil

- Oil Purity:More than 99.8%

- Mechanical impurities:Less than 0.2%

- Solvent:NO.6 solvent oil

- Residual solvent:50-500ppm

- Residual oil in cake:Less than 1%

- Supplier type:Manufacturer

- Manufacturing experience:35 years

- Texture:Mild steel and SS

We provide all the palm oil manufacturing process plant whcih included, palm oil pressing plant, palm oil solvent extraction plant and palm oil refinery plant. We can supply semi-continuous palm oil pressing equipment for and continuity sets of oil equipment. By the customers requirement we can provide all the palm oil manufacturing process lines.

Palm Oil Mill Plant - Palm Oil Mill Machine Leading

- Usage:Palm Oil

- Type:Cold & Hot Pressing Machine, Palm Oil Refinery Equipment

- Automatic Grade:Automatic

- Production Capacity:50TPD Palm Oil Refinery Equipment

- Voltage:380V

- Power(W):Based On Palm Oil Refinery Equipment Capacity

- Dimension(L*W*H):Based On Palm Oil Refinery Equipment Capacity

- Weight:Based On Palm Oil Refinery Equipment Capacity

- Certification:ISO9001

- After-sales Service Provided:Engineers available to service machinery overseas

- Raw Material:Vegetable Oil Suitable for Palm,Peanut,Palm Kernel,Palm

- Material:Stainless and Carbonless Steel

- Pretreatment Process:Cleaning,Hulling,Breaking,Soften,Flaking,Puffing,Toasting

- Cooking Oil Machinery Process:Pre-treatment,Solvent Extraction,Refining

- Solvent Extraction Process:DTDC,Miscella Toasting and Stripping,Solvent Collecting,etc

- Service:Engineer Abroad Erection

- Refining Process:Degumming,Deacidification,Deordorization,Decoloration,etc

- Process Capacity:30-500TPD

- Packing:Frame and Container

Palm kernel recovery station assures high efficiency recovery process of palm kernel after palm oil pressing processing line. It prepares for further step palm kernel oil pressing process after splitter and crushing. Depericarper (splitter). Palm kernel separates from fibers through floating dry processing during crude palm oil processing machine.

PROJECT|Customer case about Palm oil refinery machine,palm

Palm oil mill in the world about customer case, include palm oil project in Bangladesh, palm oil plantations in Indonesia, palm oil mills in Malaysia,India,Thailand etc.Palm oil production process Date 10 12, 2024; Palm kernel oil refining production line Date 10 12, 2024

GET PRICE

Palm oil manufacturing process in commercial palm oil mill

The palm oil production process in this video is standard process used in Malaysia. The engineers of Henan Doing Company has finished several palm oil mill plant project in Malaysia, so they have

GET PRICE

Palm Oil Refining Expert - Oil Mill Plant

Palm Oil Refining Process. General speaking, the palm oil refining route is quite identical. Two routes are taken to process crude palm oil into refined oils, they are chemical refining and physical refining. The methods differ basically in the way the fatty acids are removed from the oil.

GET PRICE

PROJECT|Customer case about Palm oil refinery machine,palm

Palm oil mill in the world about customer case, include palm oil project in Bangladesh, palm oil plantations in Indonesia, palm oil mills in Malaysia,India,Thailand etc.Palm oil production process Date 10 12, 2024; Palm kernel oil refining production line Date 10 12, 2024

GET PRICE

Successful Oil Milling Projects | Oil Industry

5TPD Mini Mustard Seeds Oil Plant Established in India. The 5 ton per day mini mustard seed oil plant for our client is located in Imphal, India. It is the first oil mill plant with both oil pressing

GET PRICE

Physical and Chemical Process in Palm Oil Refining Plant

Palm oil should be obtained through a series of physical and chemical palm oil refining process in the mill plant to ensure the quality of refined palm oil. Only with suitable palm oil processing equipment, the whole physical and chemical pr

GET PRICE

Palm Oil Mill Plant for sale | Palm oil machine

Palm oil mill plant for sale Our palm oil mill plant is designed for African conditions, feature a combination of imported special purpose machinery from Malaysia, together with local inputs such as buildings, steelworks, structures, tanks, vessels, etc. We have enough experience and advanced palm oil mill machinery for making palm oil, which

GET PRICE

Edible Oil Mill Machinery

a professional engineering modern enterprise specializing in various kinds of cooking oil plant machine, such as soybean oil production line,palm oil plant,rice bran oil machine and so on. Focus on the oil machinery manufacturing for 30+ years. Lingfine company is striving to become a world-leading provider of oil machinery technology and products.

GET PRICE

Manufacture Palm oil mill process,Low cost price for sale

Palm oil mill process is quite different from other oil seeds processing. Palm oil mill process includes 6 parts: Palm fruits receiving, sterilizing, threshing, digesting and pressing, crude oil clarifying and palm kernel recovery.Our palm oil mill process is low cost and energe-saving.

GET PRICE

I GOT IT - Malaysia - Palm Oil (Season 2 | 2011)

In this episode of "I Got It!", we accompany Naz and Ejahz from Indonesia to visit a palm-oil plantation. Palm-oil is very healthy and is used for the production of many different things, such as

GET PRICE

Oil Mill Plant Machinery Supplier,Oil Expellers, Oil Mill

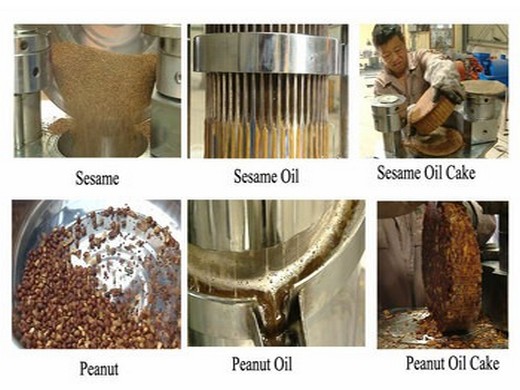

The technical teams are ready to help you design and install oil mill plant project based on your oilseed type, yield & budget. Numbers of oil mill plants for manufacturing soybean oil, peanut oil, coconut oil, sesame oil,cottonseed oil, rapeseed oil, sunflower oil, corn germ oil, palm oil and palm kernel oil, etc. have been exported & installed to various countries like India, Nigeria

GET PRICE

Guidance for Establishing a Small Scale Mustard Oil Mill Plant

We start designing and manufacturing advanced seed oil machine and turnkey mustard oil mill plant since 1990. You can get complete oil processing solutions from oilseeds preparation, oil filteration and crude oil refining. Our oil production equipment can process various seeds including linseed, sesame, cotton seed oil milling and so on.

GET PRICE

Hot Sale Machinery for Palm Oil Production Process

Palm oil processing project is a great business to invest in, which has very large market demand and profit space! Clarification Station of Palm Oil Mill. In complete palm oil productin plant, clarification is the process that ensures removal of all impurities from the crude oil.

GET PRICE